CHOOSING THE CORRECT ANCHOR CHAIN

The information found below will assist you in determining whether our chain is right for your application. All care has been taken in compiling this guide and information has been transposed from manufacturers data sheets.

HDG or AISI 316:

This refers to whether the chain is hot dipped galvanized (HDG) or made from marine grade stainless steel (AISI 316). HDG is the most common form of chain for anchoring using a gypsy or windlass. Stainless steel is prohibitively expensive yet looks beautiful when matched with a stainless anchor. The downside of stainless chain is it becomes brittle over time, when immersed in salt water. It is essential to periodically wash your chain locker and chain in fresh water. The more frequent the better.

Wire Size:

This is the diameter of the wire used to manufacture the link of chain. This then becomes the size of the chain for example 8mm, 10mm etc

Short Link:

This describes the type of chain. Short link is the preferred type of chain of marine gypsies and windlasses. It refers to shape and the pitch size (see below). That is, narrower in length than standard chain.

Pitch:

The pitch is the measurement of each link’s length measured internally. Alternatively, manufacturers may use the letter “P’ to represent pitch, for example P = 24mm.

Width:

This is the width of the chain link and is measured externally.

Specification:

This is the Standard the chain must be built to comply with. These Standards are administered by the International Standards Organisation (ISO).

DIN766 and ISO4565 are European Standards and chain designated to comply with this standard traditionally fit European windlasses. AS2321-2006 is an Australian Standard.

Always check the 10mm chain as there are two standards for this wire diameter. One is 2 mm different in link length (pitch). DIN766 has two sizes P28 and P30. DIN766 P30 is near identical to ISO4565 and AS2321-2006. If a windlass recommends DIN766 it is P28 or standard DIN766 10mm. Confused?

10mm Chain - Code Breaker

|

Grade |

Standard |

Measurement |

Subset |

External Length (mm) |

Pitch (mm) |

Width (mm) |

WLL (kgf) |

Commonly used in: |

| G3/L | DIN766 | Metric | P28 | 48mm | 28 | 34 | 950-1250 | Europe |

| G3/L | DIN766 | Metric | P30 | 50mm | 30 | 34 | 950-1250 | Europe/Britain/Australia |

| G3/L | AS2321-2006 | Metric | 50mm | 30 | 34 | 950-1250 | Australia | |

| G4/M | ISO4565 | Metric | 50mm | 30 | 34 | 1,680 | US/Europe/Britain/Australia |

Galvanizing (non-stainless chain):

Galvanizing protects the base metal by becoming a sacrificial anode. This means that the zinc will actually “sacrifice” itself to oxidation before the base metal is attacked by oxidation. Hot dip galvanized chain follows the process whereby the bare steel chain is washed in a bath of an acid and caustic solution. The cleaned chain is then dipped into a bath of hot zinc. The steel and zinc react together at 450 Celcius to form a protective anti-corrosive layer. The chain is then centrifuged to give an even coating.

Zinc Coating Thickness:

Coating thickness – Corrosion protection offered by hot dip galvanizing is linear, meaning that if a 1 mil coating thickness lasted 1 year, then 3 mils (100 u) will last 3 years under the same conditions.

In Australia the acceptable galvanising thickness is:

- 75 microns (u) or 3 mils for marine grade anchor chain (periodic use)

- > or = 100 microns (u) or 4 mils for marine grade mooring chain

1 mils (thousandths of inch) = 25.4 u (microns)

Steel Grade:

Short link galvanized chain is usually available in standard grade steel (Q235) or high quality (20Mn2). 20Mn2 is by far superior.

Q235 is low tensile chain. 20Mn2 is medium/high tensile chain.

Q235 has a tensile force (see definition below) of 0.370kN whilst 20Mn2 steel has a tensile force of 0.785kN.

Q235 has a yield strength (see definition below) of 0.235kN whilst 20Mn2 steel has a yield strength of 0.590kN.

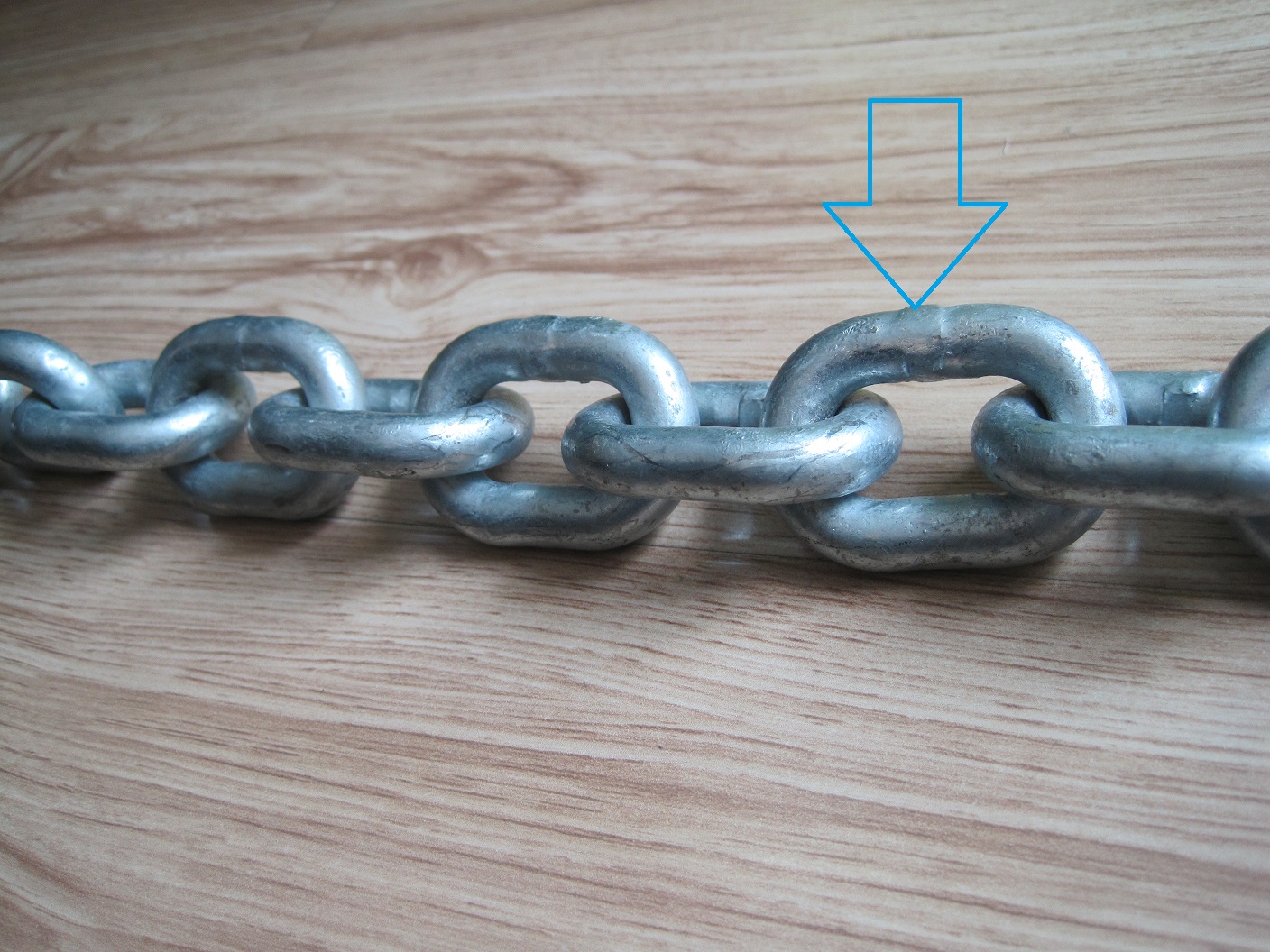

Chain Welding:

Short link chain welding can either be semi automatic or automatic. Automatic welding is far smoother and consistent without weld deformation or bumps. See images below:

SHORT LINK CHAN - Automatic Welding SHORT LINK CHAIN - Semi-Automatic Welding

Grade:

The Grade denotes strength rather than any physical measurements of a link. The higher the grade letter M (20Mn2) versus L (Q235) and G4 (20Mn2) versus G3 (Q235) the stronger the chains. Note: alphabetical delineation of chain is the more contemporary method of classification.

Working Load (WLL):

This is the load that the manufacturer recommends you never exceed. This is to allow for wear and tear over the years you'll be using it. WLL is usually 20 to 25% of the chains maximum tensile force or Breaking Load (BL). WLL is measured in Kilograms force (kgf).

Proof Force (PL):

This is also called Proof Load. This is the load the chain was loaded to in the factory during the testing procedure. Proof Load is normally 50% of the chains maximum tensile strength or Breaking Load (BL) and is usually referred to in Kilonewtons (kN).

Tensile Force or Breaking Load (BL):

This is the load at which the chain will fail. This is measured by representative testing. It is quite possible the chain will exceed the number of Kilonewtons (kN) stated.

Yield Strength (BL):

This is the stress at which a material begins to deform plastically. It is quite possible the chain will exceed the number of Kilonewtons (kN) stated.